VINcoPress Technology

Vincotech’s direct pressed substrate technology

The VINcoPress technology is aiming for superior thermal performance with improved reliability. The novel power module packaging technology presses the entire substrate to the heatsink, directly and evenly. It distributes pressure uniformly avoiding uncontrolled force to the substrate and eliminates the cracking risk during assembly.

Key features

- Direct pressed substrate

- Homogeneous pressure and Rth value distribution

- Rugged and reliable heat sink assembly

Key benefits

- Higher power capability

- Increased power density

Aluminum Nitride (AlN) Substrates

More choices for best application fit

It takes ceramic materials with higher thermal conductivity to boost baseplate-less power modules current-carrying capability. Aluminum Nitride (AlN) can reduce the thermal resistance from semiconductor junction to heatsink while the VINcoPress technology maintains rugged and reliable heat sink assembly.

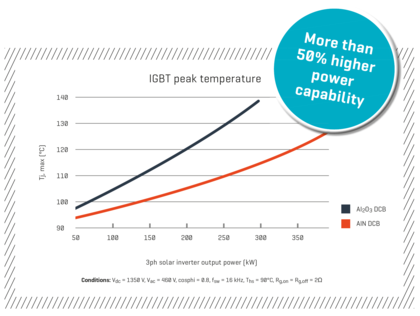

VINcoSIM, our integrated simulation environment. served to benchmark AlN DCB's peak junction temperature In comparison with Al2O3 using a 3-level NPC (T-type) module for a solar inverter application. It confirmed that AlN increases power capability by more than 50% at the same junction temperature.

Key features

- Increasing power modules’ current carrying capability

- Superior thermal performance

- Low thermal expansion coefficient

Key benefits

- Up to 50% more power in same power module foot print

- Power extension of existing frame size

Downloads

- Vincotech_VIN_FLYER_TECHNOLOGY_2024_ONLINE.pdf – PDF, 977 KB